In a non-regular feature that we will not be calling “Phoenixville Phriday,” Hoxsie is going to step away from chronicling historical trivia of its ancestral lands and momentarily turn its attention to the history of its new hometown, Phoenixville, PA. Phoenixville was a small steel town that also cranked out finished bridges; if you chance to drive across the Troy-Menands Bridge, you’re being kept out of the Hudson by one of the company’s works. The Manhattan Bridge is probably their grandest work, but hundreds of their graceful structures spanned rivers and ravines all over the place. In 1873, “The Manufacturer and Builder” wrote effusively of The Phoenixville Bridge Works:

One of the most encouraging signs of progress, as well in artistic taste as in ingenious application of scientific principles, are the beautifully illustrated catalogues or albums from prominent manufacturing establishments from time to time issued and distributed among those interested. We have one of these before, published by Clarke, Reeves & Co., of the Phoenix Iron Company, at Phoenixville, office 410 Walnut street, Philadelphia, Pa., which company can concentrate all their resources upon bridge building to such a degree as to turn out one hundred feet of finished iron bridge for each working day of the year.

In these works everything is done upon the premises, and the next to worthless iron ore from the mine is, by a succession of operations, changed into the most elegant structures for conveying passengers and merchandise across rivers and over valleys. It is something marvelous to see a single company which does so much on their premises, from the manufacture of pig-iron to the final machine labor that completes the most elaborate structures ready for erection . . .

Messrs. Clarke, Reeves & Co., who make iron bridge-building a specialty, are prepared to construct any style of wrought-iron bridges according to any specified dimensions and weight, but at the same time call the attention of engineers and railway men to that style of bridge which they have been building for the last five years, which has stood the test of use, with the marked approbation of experts in these matters, and in which the material is judiciously distributed, containing nowhere any of it that does not directly contribute to its strength, a feature which cannot be claimed for the majority of bridges in existence.

[In general, in the late 19th century, there was no such thing as praise too florid. But read on, and see if you can spot the Schenectady connection.]

This special style referred to is that kind of truss which was originally developed in wood by Pratt, and in iron by Whipple, and being proved by experience especially adapted for railroads, it is now more in use here than any other . . .

Messrs. Clarke, Reeves & Co. have built some 70 or 80 railroad bridges, of a total length of nearly 40,000 feet, or over 7 miles, which, notwithstanding being much stronger and more reliable than other styles, were cheaper for reason of their facilities on account of reduplication of parts, and lessening as well the cost of erection as of manufacture.

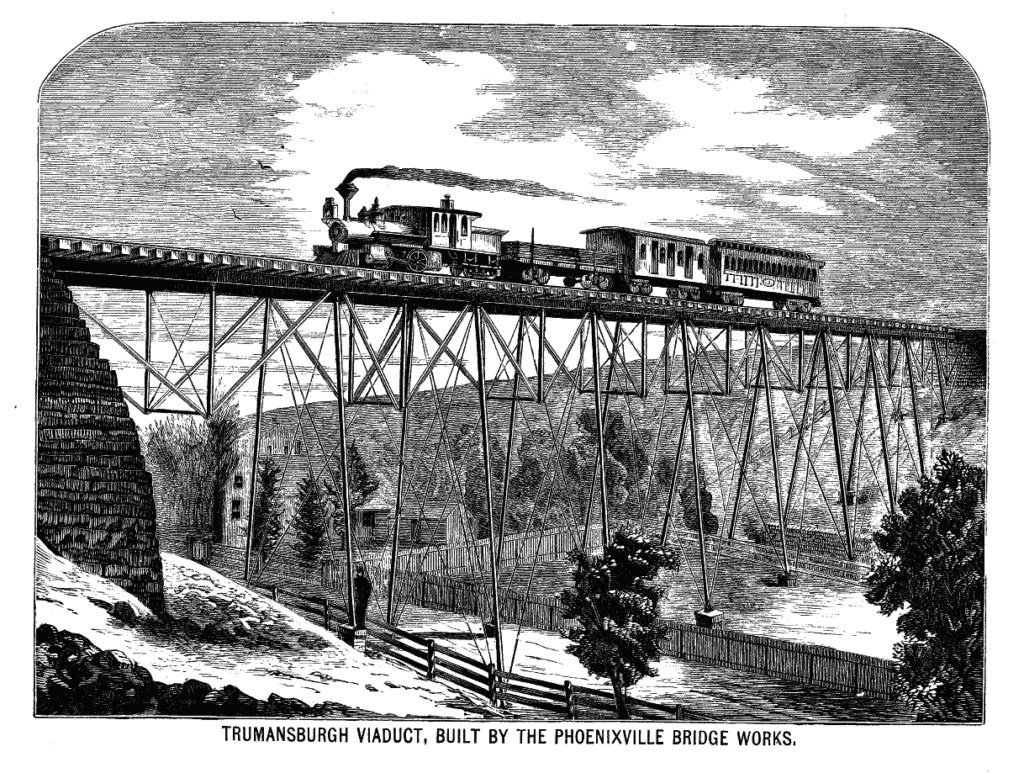

We give on the opposite page an engraving taken from a photograph of the Trumansburgh [sic – it’s Trumansburg, N.Y.] viaduct on the Geneva & Ithaca Railroad. This road runs along the west shore of Cayuga Lake, is about 42 miles long, and connects these two flourishing inland cities, and will eventually become a great coal feeder to central New York and Canada . . . The road crosses several streams flowing into Seneca Lake, over one of which is built this structure, which is 300 feet long, about 40 feet high. It is made of Phoenix posts and rolled beams well braced together, so that trains cross it at full speed without vibration. This firm also furnished the other bridges and viaducts, and have recently finished on the Geneva, Ithaca & Elmira Railroad tow much larger viaducts; one at a place called Deep Gorge, 500 feet long, and 125 feet deep; another over Block House Hollow, 600 feet long, and 80 feet deep. These viaducts cost about $60 per lineal foot, and are altogether the most economical mode of crossing deep hollows with a permanent structure. The rapidity with which they can be constructed is also a matter of great importance to railway companies.

These two viaducts, 1,100 feet long and averaging 100 feet high, were completed and passed trains over in little over three months after the order was given for their construction. They could have been done in two months if the railroad company had been ready for them. All this will give a clear idea of the simplicity, strength, economy, and adaptability of this system for all kinds of localities.

We will say in conclusion that the Phoenixville Iron Works, where these bridges are built, are among the oldest in the United States, being erected in 1790, and passing, in 1827, into the possession of the late Daniel Reeves, who by his energy increased their capacity, till they now employ constantly over 1,500 hands, being now one of the largest manufactures of iron bridges in the country. They ship their bridges to Canada and South America, and are now in negotiation for large orders in British India.