Well, we’re on a bit of a Cohoes jag, and why not? The Spindle City sometimes had a bit of an inferiority complex, failing to get the respect of the Capital City or the Collar City, and after its boom it was always a working class mill town. But what a working class it had. The canals built by the Cohoes Company provided cheap power to mills throughout the city, and the grandest of them all was built at the head of the canals.

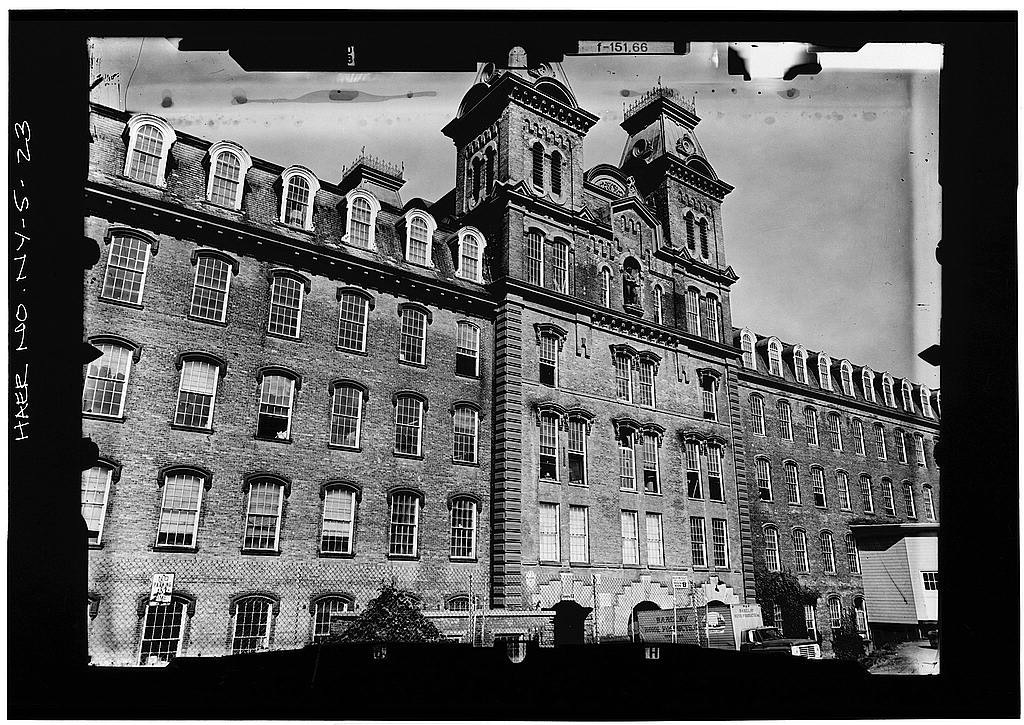

First opened in 1837, the Harmony Manufacturing Company grew for years; with a change in ownership in 1850, it acquired other mills in the city while growing itself. “The existence of a manufacturing concern of such magnitude has of course been of the utmost benefit to Cohoes in a business point of view, and contributed largely to its prosperity. Through its means large accessions have been made to the population, and the constant expenditures made by the corporation in wages, in the erection of buildings and in various improvements have been of marked advantage to the commercial interests of the place,” Arthur Masten wrote in his The History of Cohoes, New York. “Their factory buildings are all handsomely constructed, and the grounds connected with them tastefully laid out; the streets and sidewalks adjacent to their property are kept in the best condition, and the well built blocks of tenements which have been erected in different localities – more particularly on the West Harmony – are creditable additions to the buildings of the city. Of these tenements, which are nearly 1000 in number, over half have been erected since 1860… The tenements are let to the operatives at a merely nominal price, and in this, as in all other respects, the company has manifested a laudable regard for the comfort of those in its employ.”

In the 1870s, Harmony owned seven mills. One, Two and Three were built by the company; Four was the former Ogden mill, and Five was the former Strong mill. There was also a jute mill and a bag mill. Despite an economic downturn in the mid-1870s, Harmony employees took a reduction in wages but saw minimal layoffs, and the mills in total employed 4,121 operatives in 1876, working at 5,650 looms and 258,054 spindles. Mill No. 3, the Mastodon mill, employed 1639 people at 2,654 looms, with 125,936 spindles in its expanse. The company processed 13,700,000 pounds of cotton and 2,240,000 pounds of jute that year, producing: 79,500,000 yards of printing cloths, percales, wigans, and jaconets; 600,000 seamless bags; 2,130,000 pounds of jute goods; and 3,000 bales of cotton batting. Annual production was said to be $3 million.

Though by far the largest, Harmony was hardly the only operation that gave the Spindle City its nickname. Many of the improvements in the manufacture of fabric were made in Cohoes, and the knitting machines themselves were made there. Masten, writing when the Long Depression was still going strong, said “It is impossible at present to give accurately the statistics of production of the seventeen knitting mills which are now in operation. Since the panic [of 1873] many of them have been shut down for greater or less periods, and the number of operatives employed, and amount of wages paid, have varied; the grade and style of the goods manufactured have been changed from time to time to suit the market, so that the amount of annual production cannot be exactly named.” But he did name the mills themselves, which were:

- The Troy Manufacturing Company

- The Root Manufacturing Company

- H. Parsons & Co.

- The Atlantic Mill

- The Ranken Knitting Co.

- American Hosiery Mill

- The Victor Mill

- The Empire Mill

- The Star Knitting Co.

- The Adams Mill

- The Ontario Mill

- The Mohawk Mill

- The Erie Mill

- The Enterprise Mill

- The Diamond Mill

- The Globe Mill

- The Pine Grove Mill

In 1867, things got so bad that all the 15 mills then open in Cohoes agreed to shut down at once. The Troy Times reported that they employed 2,000 people (which doesn’t line up with Masten’s count; I think it’s the amount still employed, and about the same number was laid off), and that all

“have agreed to shut down by the 15th of August. Some of them have already ceased running, and all will do so as they respectively use up the stock on hand. The proprietors are buying no new stock whatever. The stock of shirts and drawers on hand is now enormous. They have been accumulating for months, because no profitable or even saving market was open to them. The proprietors show that it costs them $11[.]20 per dozen to manufacture shirts and drawers, and these are now and for some time have been selling in the great markets at $10[.]50 per dozen.”

The troubles continued at least through October of that year, when Harmony was running at some strength but other mills were laying off, and it was reported that 2,000 were out of work.

Textiles were hardly the only manufactures in Cohoes. Daniel Simmons and Horace Silliman established an axe and edge tool factory in 1835 (succeeding the original Simmons business in far-off Berne), and their products were said to have a worldwide reputation. The Weed & Becker Manufacturing Co. produced 100 dozen axes and 75 dozen tools daily in 1876. The Empire Edge Tool Works made up to 15,000 dozen axes and tools a year. The Ten Eyck Axe Manufacturing Company made 500 tools a day. The Cohoes Rolling Mill put out 6000 tons of bar and band iron a year. The Empire Tube Works made 3,000,000 feet of gas and steam pipe. Campbell and Clute made knitting machinery for the mills. The Cohoes Iron Foundery [sic] and Machine Shop made cotton, woolen and flouring mill machinery as well as architectural iron work. Tubbs & Severson made knitting machinery.

In those days before corporate names were conglomerated into meaninglessness, pretty much every company in Cohoes had what it did right up there on the sign: The Cohoes Knitting Needle Factory, the Sash and Blind Factory, the Cohoes Bedstead Factory, the Cohoes Straw Board Company, McMartin Flouring Mill, American Soap Company, Cohoes Lime and Cement Company, the Cohoes Warp and Thread Company. Trost and Bezner Manufacturing broke that trend, making furniture and other wooden items. There were five paper box factories, all with some intimation that they made boxes contained in their names.

Remarkably, Cohoes was then home to one daily paper and four weeklies, including one in French, as Cohoes had attracted a significant French Canadian population. It was also the home to four banks in 1876.

Leave a Reply