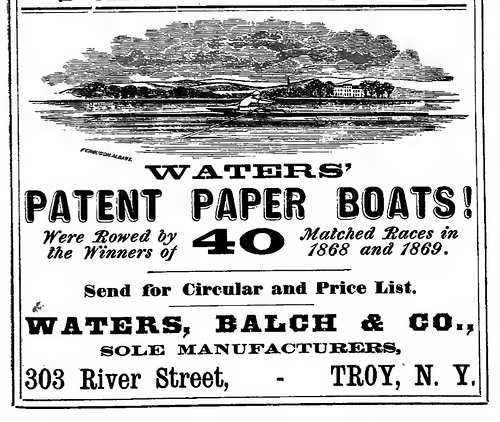

Nathaniel Bishop didn’t originally set out to paddle from Troy to the Gulf of Mexico in a paper canoe. He had started from Quebec in a traditional wooden boat, but on arriving at Albany he decided that he needed to jettison both his paddling companion and his heavy boat. “After a journey of four hundred miles, experience had taught me that I could travel more quickly in a lighter boat, and more conveniently and economically without a companion. It was now about the first week in August [1874], and the delay which would attend the building of a new boat especially adapted for the journey of two thousand miles yet to be travelled would not be lost, as by waiting a few weeks, time would be given for the malaria on the rivers of New Jersey, Delaware, and Maryland, and even farther south, to be eradicated by the fall frosts.” But it’s clear that even before arriving in the area, he knew of the merits of the paper boats being made by George Waters just north of Troy, which were winning all sorts of races at a time when America was having a bit of a canoe racing craze. Having completed his journey, Bishop extolled their virtues:

Inquiries regarding the history and durability of paper boats occasionally reach me through the medium of the post-office. After all the uses to which paper has been put during the last twenty years, the public is yet hardly convinced that the flimsy material, paper, can successfully take the place of wood in the construction of light pleasure-boats, canoes, and racing shells. Yet the idea has become an accomplished fact. The success of the victorious paper shells of the Cornell College navy, which were enlisted in the struggles of two seasons at Saratoga, against no mean antagonists, — the college crews of the United States, — surely proves that in strength, stiffness, speed, and fineness of model, the paper boat is without a rival.

When used in its own peculiar sphere, the improved paper boat will be found to possess the following merits: less weight, greater strength, stiffness, durability, and speed than a wooden boat of the same size and model; and the moulded paper shell will retain the delicate lines so essential to speed, while the brittle wooden shell yields more or less to the warping influences of sun and moisture.

Bishop also gives us the colorful story of how paper boats, made from layers of manila, varnished thickly, came about:

Mr. George A. Waters, the son of the senior member of the firm of E. Waters & Sons, of Troy, New York, was invited some years since to a masquerade party. The boy repaired to a toy shop to purchase a counterfeit face; but, thinking the price (eight dollars) was more than he could afford for a single evening’s sport, he borrowed the mask for a model, from which he produced a duplicate as perfect as was the original. While engaged upon his novel work, an idea impressed itself upon his ingenious brain. “Cannot,” he queried, “a paper shell be made upon the wooden model of a boat? And will not a shell thus produced, after being treated to a coat of varnish, float as well, and be lighter than a wooden boat?”

This was in March, 1867, while the youth was engaged in the manufacture of paper boxes. Having repaired a wooden shell-boat by covering the cracks with sheets of stout paper cemented to the wood, the result satisfied him; and he immediately applied his attention to the further development of his bright idea. Assisted by his father, Mr. Elisha Waters, the enterprise was commenced “by taking a wooden shell, thirteen inches wide and thirty feet long, as a mould, and covering the entire surface of its bottom and sides with small sheets of strong Manila paper, glued together, and superposed on each other, so that the joints of one layer were covered by the middle of the sheet immediately above, until a sheet of paper had been formed one-sixteenth of an inch in thickness. The fabric thus constructed, after being carefully dried, was removed from the mould and fitted up with a suitable frame, consisting of a lower keelson, two inwales, the bulkhead; in short, all the usual parts of the frame of a wooden shell, except the timbers, or ribs, of which none were used — the extreme stiffness of the skin rendering them unnecessary. Its surface was then carefully waterproofed with suitable varnishes, and the work was completed. Trials proved that, rude as was this first attempt compared with the elegant craft now turned out from paper, it had marked merits, among which were, its remarkable stiffness, the symmetry of the hull with respect to its long axis, and the smoothness of the water-surface.”

Leave a Reply