The Albany Morning Press lived through a time of a revolution in newspaper production, and quickly took advantage of the changing technologies, using the newly invented wire services, the Mergenthaler linotype typesetter, and Hoe’s latest presses, not to mention vacuum tubes for moving paper around the office.

The telegraph was fairly new to Albany at the time the Albany Morning Express started production in 1847 – the first wire to the west connected to Utica on Jan. 31, 1846. The Associated Press began life later that year as the State Associated Press, with a main office in Albany, where news from Albany and New York was wired to Utica and sent out from that city by express on printed slips. The first daily reports were sent to newspapers on Jan. 1, 1847, and the Express was one of the original subscribers; its editor Jacob C. Cuyler was one of the incorporators.

The first edition was published from the second floor of the building one building south of the southwest corner of Beaver and Green streets, which then was the publishing district. (Be shocked to learn that the space is currently a parking lot.)

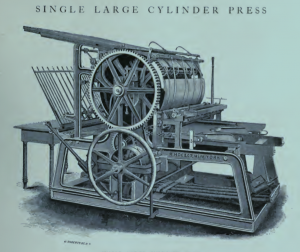

“With a great deal of warrantable pride the announcement was made that the paper was printed ‘on a first rate Napier press.’ This was the name of the first generally recognized improved printing press. Up to 1835 there was in general use only hand presses, and the Napier was an innovation which was followed by what was known as the Hoe lightning press patented July 14, 1847. So it will be seen that the Express and rapid printing came into the world at about the same time.”

The Napier press was the first to use grippers to pull the sheets around the cylinder and to deliver them after the impression. Hoe & Co. made the first flat bed and cylinder press in the United States. This was cutting edge technology, but it isn’t surprising, as Albany was really a major publishing center – it is said that Van Benthuysen’s printing operation on Columbia Street used the first steam-driven press in the country.

The Express’s coverage of its 50th anniversary included an in-depth view of its typesetting capabilities in 1897, which are fascinating to those of us who once set type for a living:

“Advertisements received at the counting-room desk and all editorial and news ‘copy’ are placed in cylindrical leather pouches and shot directly to the compositing rooms through tubes connecting with all departments and converging at the foreman’s desk.

The ‘take’ is given out to the operator, who, seated at the keyboard to the type-setting machine, produces newly cast lines of type which are deposited by the machine in the order which they are set and are removed in columns to the press upon which the proof sheet is printed. When corrected the type is placed on large stone beds where by means of wedges called quoins it is made up into pages ready to be lowered to the press rooms. The composition of 10,000 ems for ten hours’ of type-setting by hand is considered a good day’s work. There is the possibility of largely exceeding that by adept and rapid compositors, perhaps, most of whom could do better in spurts. But the average hand composition will not exceed that measure. Each of the five Mergenthaler type-setting machines will turn out more than five thousand ems an hour or between thirty and forty thousand in an ordinary day’s work, such as is required on the Express; that is during the hours beginning at 6:45 p.m. and ending at 2:45 or 3 a.m., with an intermission for lunch.

Every day after the type is used it is thrown into the melting pots and recast for the following day, replenishing the old with new metal as often as necessary. So that both the Journal and the Express are printed from new type every day. The casting of each type is all done when the operator presses down the key corresponding to the letter. The machine occupies comparatively little space, makes very little muss and does not give out the heat and particles of flying dust customary in foundries for casting metal. In fact the several small boxes in the cases used in hand composition, always gathered dust from the room and dirt from the distribution of type which filled the air with more dirt than comes from these machines.

The linotype was not only five times speedier than setting type letter by letter, but casting new characters for every single edition meant that the paper looked clean and free of broken type.