As mentioned before, Henry Burden took charge of the Troy Iron and Nail Factory in 1822 when it was a smallish factory at the top of the Wynantskill in Troy, where Mill Street runs up the hill to Campbell Avenue today. “With more than ordinary foresight he caught glimpses of that future in which there were immediate and immense demands for the various articles produced by his machines, and he failed not, with excellent judgment, to make, in time, the necessary preparations for this enlarged business.” [Note to self: have loving daughters write my gushing biography.] He bought up stock in the company and by 1835 owned half its stock, and through assignment of his patents for spike and horseshoe machines received 30 percent of the net earnings of the entire works. In 1848 he gained the whole works, after which it was known as H. Burden or H. Burden & Sons.

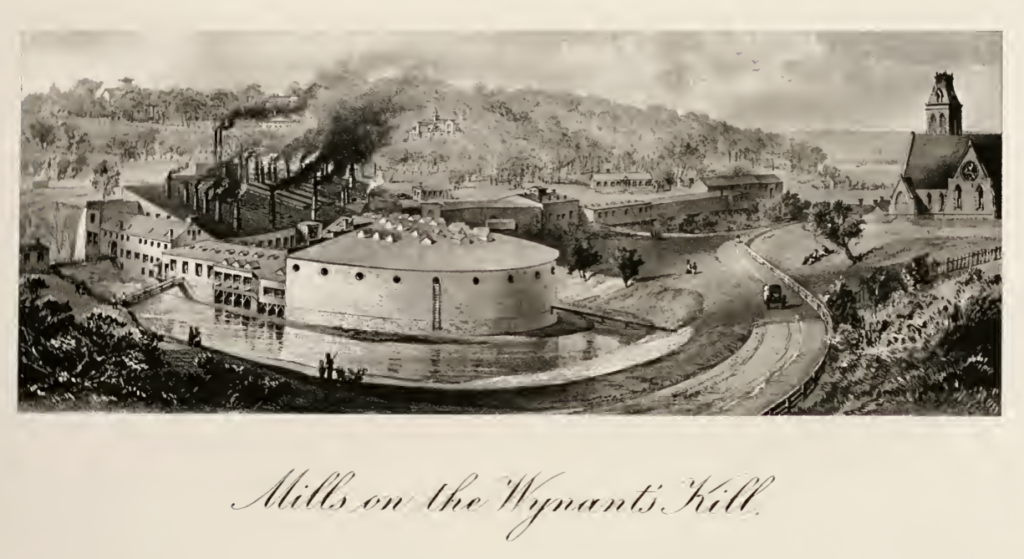

The old nail factory became known as the Upper Works. By the time of his death in 1871 it included:

- A rolling mill and puddling forge

- A horseshoe factory (two buildings)

- A rivet factory

- A horseshoe warehouse, semicircular, containing 16 large bins, in which can be stored 7,000 tons of horseshoes (evident in the middle of the graphic)

- A scraphouse and shop

- Here also are the general business office, a supply store, a rivet warehouse, the stables, etc.

Woodside Presbyterian Church, built in 1869, is evident in this view. The course of the Wynantskill has been changed since then – the oxbow shown here is now a jughandle along Mill Street. With the exception of the church, no other trace of the works really remains, except perhaps some walls and remnants in the woods along the creek.

The Lower Works were developed on the Hoyle farm, 45 acres between the Hudson River railroad (about where Route 4 is now) and the river. The lower works were driven by steam power, and included:

- Two blast furnaces, each 65 feet high and 16 feet at their boshes, with two casting-houses

- Two stockhouses

- An engine-room

- A puddling forge

- A rolling-mill

- A swaging shop

- A punching shop

- A horseshoe warehouse

- A square building, containing offices, blowroom, etc.

- A machine shop

- A blacksmith shop

- A foundry

- A pattern shop

- A tin and plumbing shop

- A building containing a supply store, draughting room, laboratory, etc.

- An iron warehouse.

All of this contained 60 puddling furnaces, 20 heating furnaces, 14 trains of rolls, three rotary concentric squeezers, nine horseshoe machines, 12 rivet machines, 10 large and 15 small steam engines, 70 boilers. And one large water-wheel.

The nearby railroad was used to bring in iron ore, kaolin, sand, stone and other materials, and to ship out horseshoes and iron. There was a barge landing on the river with steam derricks for moving coal.

About the only thing remaining of all this intense industry is the Burden Ironworks Museum and the landmark Woodside Presbyterian Church, now an arts center.

Want to know more about Henry Burden? Just follow these links:

Hi there-are you still out there, I know this is dated from 2013 but I’m fascinated by Henry Burden myself, I think all you’ve compiled here is incredible!

Yes, we’re still here! Not posting as much these days because of life, but appreciate your comment!